Continuous Cement Mix Station — Real Clay 3D Ceramic Printer - 3D Potter

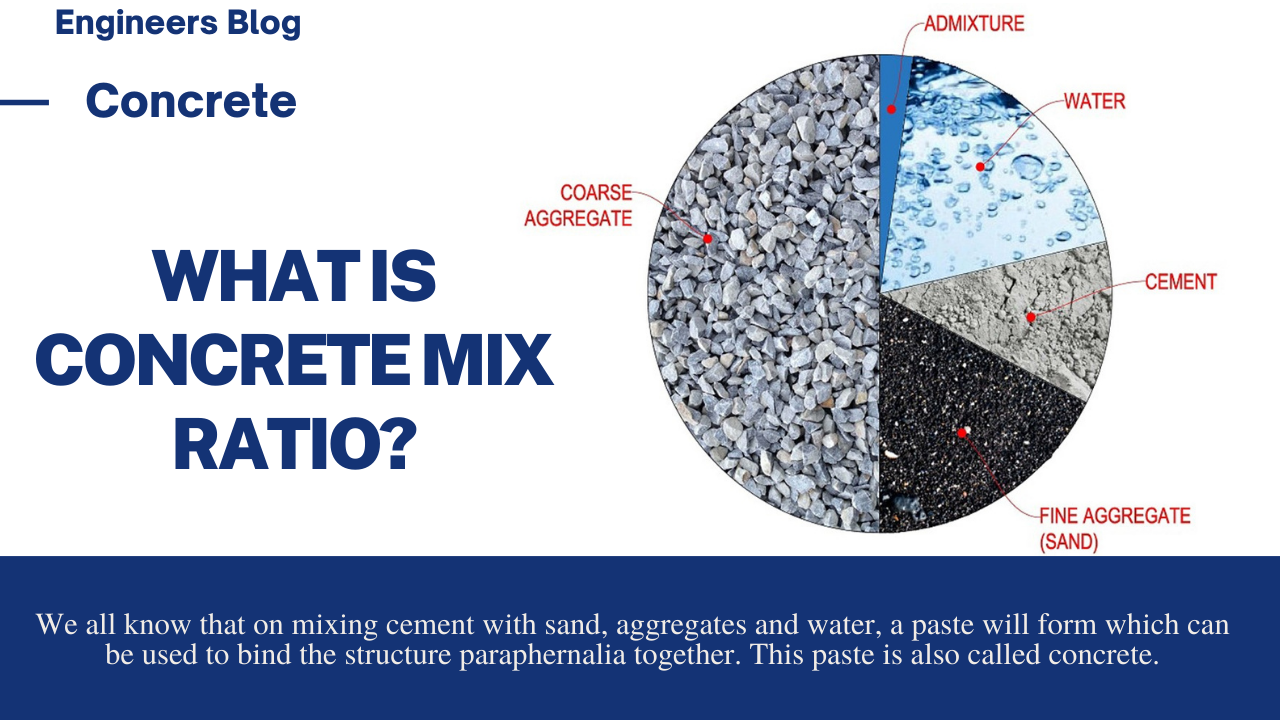

3D Potter is proud to announce the most innovative computer-controlled Mixing Station. After years of research and cooperation with Sika Corporation, the largest manufacturer of 3D printing cement, we have developed one of the most sophisticated and accurate dosing mixing machines on the market. Th

Specializing in robotics for many years we came to the conclusion that the Delta platform was under-appreciated and underutilized. After careful evaluation we determined that the many existing designs although functional lacked one major component attribute. This important aspect was structural integrity and rigidity. The Delta platform in particular is very susceptible to tower movement and wobble. Excessive movement of the Delta limits many aspects of it's design. It is not possible to carry a large payload on the effector plate (the main moving part of the Delta body). By designing the structural stable platform we are able to put the step extruded on the effector where it belongs.

By utilizing our design and engineering's experience stretching back 4 decades and the three generations of design/engineers, gives us the ability to produce a superior structure for the Delta platform. Our facility is unique in equipment; we have aircraft quality CNC machines for rapid prototyping, production and custom robotics.

Another philosophy we learned from the aircraft manufacturing facilities we owned in the past was matched hole technology was the only way to produce a rigid structure while maintaining extreme accuracy during the assembly. Our entire Delta platform is manufactured on CNC equipment and all of the machine and hole drilling is performed on the CNC machines.

Additionally we also have the ability to do large-scale custom Delta robotics to suit the many unique requirements of our customers. Not only do we produce FDM machines we are also producing food and clay extruding Delta platforms. In the near future we will be able to produce a large-scale Delta platforms for extruding not only food and clay type materials but also structural composite and other structural materials.

We have a long history of many businesses behind us with customer satisfaction being our top priority. We come from not only a robotics background but also from composites all the way up to complete aircraft manufacturing facility.

3D Potterbot's PR articles about their Real Clay 3D Ceramic Printers — 3D Potter Real Clay 3D Ceramic Printers

This is a replacement/spare piston for our extruders. This part is sent with every printer and extruder. If you would like to change tubes fast, it is

Piston — Real Clay 3D Ceramic Printer - 3D Potter

Factory Prepared Clay for Clay 3D Ceramic Printer Extruders — 3D Potter Real Clay 3D Ceramic Printers

Pumps and Mixers — 3D Potter Real Clay 3D Ceramic Printers

3D Potter - Real Clay 3D Ceramic Printers

Essential Add-ons For Ceramic 3D Printers — 3D Potter Real Clay 3D Ceramic Printers

3D Potter / SIO-2 prepared 3D printer clay.

Essential Add-ons For Ceramic 3D Printers — 3D Potter Real Clay 3D Ceramic Printers

3D Potter - Real Clay 3D Ceramic Printers

Wall Mount Extruder/Tube Loader 3600/4000ml (Like New) — Real Clay 3D Ceramic Printer - 3D Potter

Wall Mount Extruder/Tube Loader 3600/4000ml (Like New) — Real Clay 3D Ceramic Printer - 3D Potter

3D Printing Clay at 250mm per second!

3D Potter's technology facilitates clay 3D printing - 3Dnatives

Frequently Asked Questions (FAQ) about Clay 3D Ceramic Printers and 3D Potterbot — 3D Potter Real Clay 3D Ceramic Printers